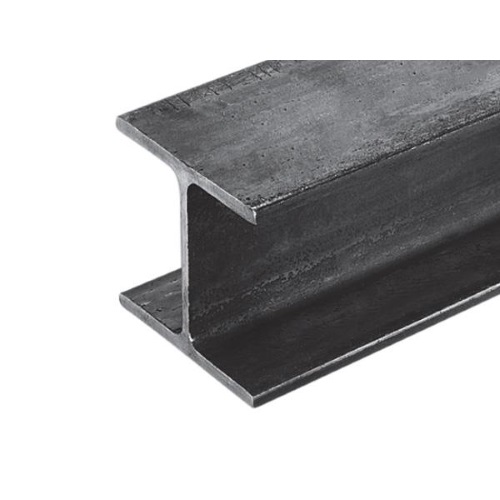

Structural steel shape

I beam and H beam are widely used in the construction industry in order to provide support buildings and load-bearing walls.

They are available in a variety of standard sizes and the options shall be based on demanding applications. I shaped steel can be used as steel beams and steel pylons. I beam is widely used in the design of load bearing structures, decorative structures in industrial areas, buildings, structural steel buildings in Industry and Civil. With the shape of I so the steel has bearing capacity and elasticity, strong and beautiful form, shall flatters the beauty of works structure.

| I-shaped steel: Standard size and thickness | |||||

| H (mm) | B (mm) | t1(mm) | t2 (mm) | L (m) | W (kg/m) |

| 100 | 55 | 4.5 | 6.5 | 6 | 9.46 |

| 120 | 64 | 4.8 | 6.5 | 6 | 11.50 |

| 150 | 75 | 5 | 7 | 12 | 14,0 |

| 194 | 150 | 6 | 9 | 6/12 | 29.9 |

| 198 | 99 | 4.5 | 7 | 6/12 | 18,2 |

| 200 | 100 | 5,5 | 8 | 6/12 | 21,3 |

| 248 | 124 | 5 | 8 | 6/12 | 25.1 |

| 250 | 125 | 6 | 9 | 12 | 29,6 |

| 298 | 149 | 5.5 | 8 | 12 | 32,0 |

| 300 | 150 | 6,5 | 9 | 12 | 36,7 |

| 346 | 174 | 6 | 9 | 12 | 41,4 |

| 350 | 175 | 7 | 11 | 12 | 49,6 |

| 396 | 199 | 7 | 11 | 12 | 56,6 |

| 400 | 200 | 8 | 13 | 12 | 66,0 |

| 446 | 199 | 8 | 13 | 12 | 66,2 |

| 450 | 200 | 9 | 14 | 12 | 76,0 |

| 482 | 300 | 11 | 15 | 12 | 111,0 |

| 496 | 199 | 9 | 14 | 12 | 79,5 |

| 500 | 200 | 10 | 16 | 12 | 89,6 |

| 500 | 300 | 11 | 18 | 12 | 128,0 |

| 588 | 300 | 12 | 20 | 12 | 147,0 |

| 596 | 199 | 10 | 15 | 12 | 94,6 |

| 600 | 200 | 11 | 17 | 12 | 106,0 |

| 600 | 300 | 12 | 20 | 12 | 151,0 |

| 700 | 300 | 13 | 24 | 12 | 185,0 |

| 800 | 300 | 14 | 26 | 12 | 210 |

| 900 | 300 | 16 | 28 | 12 | 240 |

H-shaped steel is capable of efficient construction: Steel structures can be developed into any shape, bolted or welded together in construction. Steel structure can be erected immediately after the material is supplied on the steel body, while the concrete must be maintained at least 1-2 weeks after pouring before construction can continue, ensure that the construction shall be completed on schedule.

| H (mm) | B (mm) | t1(mm) | L (m) | W (kg/m) |

| 50 | 32 | 4,4 | 6 | 4,48 |

| 60 | 36 | 4,4 | 6 | 5,90 |

| 80 | 40 | 4,5 | 6 | 7,05 |

| 100 | 46 | 4,5 | 6 | 8,59 |

| 120 | 52 | 4,8 | 6 | 10,48 |

| 140 | 58 | 4,9 | 6 | 12,30 |

| 150 | 75 | 6,5 | 6 | 18,60 |

| 160 | 64 | 5 | 6 | 14,20 |

| 180 | 68 | 6 | 12 | 18.16 |

| 180 | 68 | 6.5 | 12 | 18.4 |

| 180 | 75 | 5,1 | 12 | 17.4 |

| 200 | 73 | 6,0 | 12 | 21,30 |

| 200 | 73 | 7,0 | 12 | 23,70 |

| 200 | 76 | 5,2 | 12 | 18,40 |

| 200 | 80 | 7,5 | 12 | 24,60 |

| 240 | 90 | 5,6 | 12 | 24 |

| 250 | 90 | 9 | 12 | 34,60 |

| 250 | 78 | 6.8 | 12 | 25,50 |

| 280 | 85 | 9,9 | 12 | 34,81 |

| 300 | 90 | 9 | 12 | 38,10 |

| 300 | 88 | 7 | 12 | 34.6 |

| 300 | 90 | 12 | 12 | 48.6 |

| 380 | 100 | 10.5 | 12 | 54.5 |